Commercial environments demand robust solutions for moisture protection. A waterproof fitting ensures equipment stays safe and functional in harsh conditions.

- Statistical tests show connectors with advanced locking mechanisms last longer under vibration and humidity.

- Design and assembly quality greatly affect waterproofness and longevity.

Key Takeaways

- Waterproof fittings protect electrical equipment from water, dust, and corrosion, preventing costly failures and downtime in commercial environments.

- Choosing fittings with proper certifications and ratings, like IP67 or IP68, ensures safety, compliance, and long-lasting performance in harsh conditions.

- Proper installation and regular maintenance of waterproof fittings extend their lifespan and keep commercial systems reliable and safe.

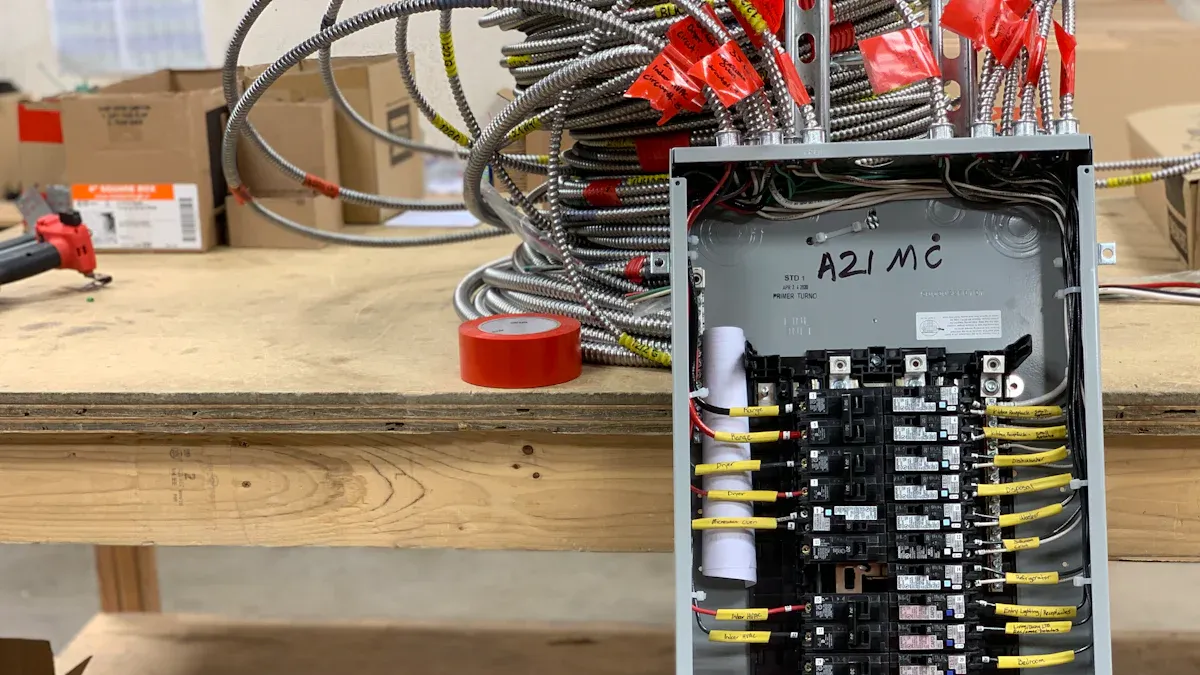

Waterproof Fitting Importance in Commercial Installations

Preventing Equipment Failure and Downtime

A waterproof fitting protects electrical systems from water, dust, and other contaminants. Many industries rely on these fittings to keep equipment running smoothly. When water enters electrical components, it can cause corrosion, short circuits, and even total equipment failure. This leads to costly repairs and unexpected downtime.

- Waterproof connectors are essential in industries such as marine, outdoor construction, agriculture, and industrial washdown areas to prevent water ingress that can cause equipment failure.

- Features like IP67 and IP68 ratings ensure connectors can withstand dust and water immersion, protecting electrical systems from corrosion and short circuits.

- In marine applications, waterproof connectors prevent corrosion and electrical failures critical for safety and operational reliability.

- Outdoor construction and agricultural equipment rely on waterproof connectors to maintain uninterrupted functionality despite exposure to rain, dirt, and mechanical strain.

Waterproof fittings use corrosion-resistant materials and advanced sealing technology. These features extend the lifespan of equipment and reduce the risk of breakdowns. Many companies now use modular designs and integrated sensors to monitor conditions and prevent failures before they happen.

Ensuring Safety and Compliance

Safety remains a top priority in commercial installations. Waterproof fittings help meet strict industry standards and regulations. They keep electrical systems safe, even in harsh environments with moisture, salt, or chemicals.

Tip: Regular inspections and proper installation of waterproof fittings can help maintain compliance and prevent safety hazards.

Industrial washdown areas, for example, require connectors that resist powerful water jets during cleaning. These fittings protect workers and equipment by preventing accidental shocks and electrical fires. By choosing the right waterproof fitting, companies ensure both safety and regulatory compliance.

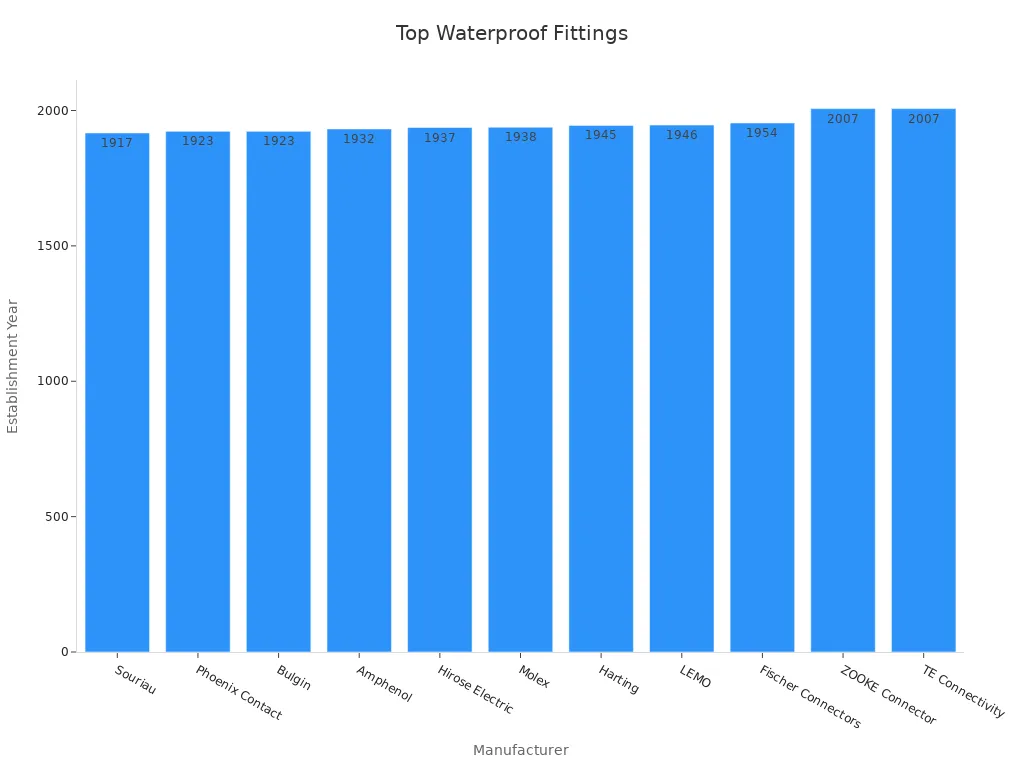

Top 10 Waterproof Fitting Solutions for Commercial Use

The demand for reliable waterproof solutions continues to rise in commercial and industrial sectors. Rapid urbanization and infrastructure growth in regions like China, the USA, and Germany drive this trend. Market reports show that waterproof fittings play a critical role in protecting electrical systems and ensuring long-term performance. Manufacturers such as ZOOKE Connector, Phoenix Contact, and LEMO lead the industry with innovative products and high-quality standards.

IP68 Cable Glands

IP68 cable glands provide a secure seal for cables entering enclosures. These glands prevent water and dust from reaching sensitive electrical components. The RNBU cable gland, for example, holds UL certification and supports a wide temperature range. It offers reliable sealing in both static and dynamic environments. International certifications such as CE, CCC, and UL confirm the safety and durability of these products. Installers choose IP68 cable glands for their easy installation and long-term performance in commercial settings.

| Region/Market | Certification(s) | Key Standards/Tests | Performance Metrics/Tests Included |

|---|---|---|---|

| European Union (EU) | CE | EN 62444, ATEX | IP68, corrosion resistance |

| North America | UL/cUL | UL 514B, CSA | Fire resistance, impact resistance |

| China | CCC | GB/T 4208 | IP protection, factory inspection |

Waterproof Junction Boxes

Waterproof junction boxes protect electrical connections from moisture, dust, and physical impacts. Manufacturers use high-impact polymers and corrosion-resistant metals to enhance durability. These boxes reduce risks such as short circuits and fire hazards. They comply with strict safety regulations and support code-compliant installations. Outdoor models feature water-tight seals and impact-resistant finishes. Many commercial projects now use smart junction boxes for remote monitoring and easier maintenance.

- Advanced materials and sealing technologies improve weatherproofing.

- Proper sizing and grounding lower the risk of overheating and electric shock.

- Accessible designs allow for quick inspection and troubleshooting.

Liquid-Tight Conduit Fittings

Liquid-tight conduit fittings shield wiring from water, oil, dirt, and chemicals. Products like ANACONDA SEALTITE® meet UL and NEC standards. These fittings work well in direct burial, concrete embedding, and outdoor installations. Flexible designs allow for easy routing around corners and in tight spaces. Corrosion-resistant materials such as stainless steel and nickel-plated brass extend service life. Specialized types meet food-grade, halogen-free, and extreme temperature requirements.

- Fittings maintain moisture seals and resist corrosion.

- UV-resistant jackets protect against sunlight exposure.

- Flexible seals prevent moisture intrusion.

Waterproof Electrical Connectors (M12/M8)

M12 and M8 connectors ensure reliable electrical integrity in harsh environments. These connectors meet IP67 and IP68 ratings, offering protection from dust and water immersion. They withstand over 500 mating cycles and maintain low contact resistance. Manufacturers use copper-zinc alloys and gold plating for enhanced conductivity and corrosion resistance. Certifications include CE, RoHS, and IEC61076-2-101. Industries such as aerospace, automotive, and automation rely on these connectors for dependable performance.

| Feature | Specification/Standard |

|---|---|

| Waterproof Rating | IP67, IP68 |

| Mechanical Durability | Over 500 mating cycles |

| Certifications | CE, RoHS, IEC61076-2-101, U.S. Military |

| Operating Temperature | -40°C to +105°C |

Weatherproof Switch Covers

Weatherproof switch covers protect switches and outlets from rain, snow, and dust. Manufacturers use durable materials like polycarbonate and cast aluminum. These covers maintain weather resistance even when devices are plugged in. Compliance with the National Electrical Code ensures safety in wet locations. NEMA 3R, 4, and 4X ratings confirm protection against water and corrosion. Proper installation by qualified electricians is essential for sealing and safety.

| Rating | Protection Features | Relevance to Longevity and Safety Compliance |

|---|---|---|

| NEMA 3R | Rain, snow, sleet protection | Outdoor durability |

| NEMA 4 | Water-tight, withstands water sprays | Moisture protection |

| NEMA 4X | Enhanced corrosion resistance for extreme conditions | Extended lifespan in harsh environments |

Sealed Compression Fittings

Sealed compression fittings deliver leak-proof performance in demanding applications. Manufacturers test these fittings for hydraulic pressure, vacuum retention, and thermal cycling. Results show zero leakage under high pressure and excellent seal integrity across temperature changes. Aging resistance tests confirm minimal degradation over time. These fittings use high-grade materials to resist thermal stress and maintain sealing efficiency.

| Test Type | Description | Key Results |

|---|---|---|

| Hydraulic Pressure Testing | Simulates operational water pressure | Zero leakage, even with fluctuating pressure |

| Vacuum Testing | Monitors gas seal integrity | Exceptional vacuum retention |

| Thermal Cycle Testing | Simulates temperature variations | Maintained seal integrity |

| Aging Resistance Testing | Simulates long-term use | Minimal degradation, intact seals |

Waterproof Grommets

Waterproof grommets provide a watertight seal for cables passing through panels or enclosures. Rated IP67, these grommets block dust and withstand temporary water immersion. They perform well in oily, greasy, and vibrating environments. Features such as o-rings and strain relief enhance sealing and durability. Compared to standard connectors, waterproof grommets offer longer service life and better reliability in moisture-prone areas.

- Rubber gaskets and potting compounds improve protection.

- Higher initial cost is offset by reduced repairs and downtime.

Stainless Steel Enclosures

Stainless steel enclosures offer robust waterproof protection for sensitive equipment. These enclosures meet IP65, IP67, and IP69K ratings, ensuring dust-tight and water-resistant performance. NEMA 3R, 4, and 6P ratings confirm suitability for outdoor and wet locations. Stainless steel resists corrosion, making these enclosures ideal for harsh environments such as vehicle wash areas and industrial sites.

| Rating System | Rating Examples | Protection Description | Waterproof Relevance |

|---|---|---|---|

| IP | IP65, IP67, IP69K | Dust-tight, water jets, immersion | Prevents water ingress under various conditions |

| NEMA | 3R, 4, 6P | Rain, hose water, submersion | Certifies for outdoor and wet location use |

Waterproof Push-Button Switches

Waterproof push-button switches operate reliably in wet and dusty environments. High IP ratings such as IP65, IP67, and IP68 certify resistance to water and dust. Manufacturers use corrosion-resistant materials like stainless steel and durable plastics. Advanced sealing technologies prevent moisture entry, reducing the risk of malfunctions. These switches undergo rigorous testing for prolonged water exposure and are suitable for marine, automotive, and industrial equipment.

- Proper installation with waterproof O-rings maintains integrity.

- Regular inspection and cleaning extend switch lifespan.

Waterproof LED Lighting Fixtures

Waterproof LED lighting fixtures deliver consistent performance in industrial and outdoor settings. Accelerated aging tests, including Highly Accelerated Stress Test (HAST) and Temperature-Humidity Bias Life Test (THB), validate their durability. These tests expose fixtures to high temperatures, humidity, and pressure for up to 1,000 hours. Results show minimal electrical, thermal, and optical degradation. Waterproof LED fixtures provide long-term reliability and energy efficiency in harsh environments.

Note: Upgrading to waterproof LED lighting reduces maintenance costs and improves safety in commercial installations.

How to Select the Right Waterproof Fitting

Assessing Environmental and Application Needs

Selecting the right waterproof fitting starts with understanding the environment and application. Engineers test products in chambers that simulate rain, humidity, and extreme temperatures. These tests help identify weak points and improve product design. Industries such as automotive, aerospace, and outdoor equipment rely on these tests to ensure durability. Specialized chambers, like thermal shock and pressure jet devices, push fittings to their limits. Real-time monitoring and automation make these tests more accurate. These steps confirm that fittings can handle harsh conditions and meet installation needs.

Understanding Compliance and Certification

Industry standards guide the selection process. Organizations use military and commercial standards to test waterproofness and resilience. Standards such as MIL-STD 750, NEMA 250, IEC 60529, and ISO 20653 set the requirements for performance. The table below shows how IP ratings define protection levels:

| IP Rating | Protection Against Solid Objects | Protection Against Water |

|---|---|---|

| IP68 | Dust tight | Immersion beyond 1 m |

| IP67 | Dust tight | Immersion up to 1 m |

| IP58 | Dust protected | Immersion beyond 1 m |

| IP57 | Dust protected | Immersion up to 1 m |

Meeting these standards ensures that the waterproof fitting will perform as expected in commercial settings.

Installation and Maintenance Best Practices

Proper installation and maintenance extend the life of waterproof fittings. Technicians prepare pipes by removing old solder and smoothing surfaces. They use tools to measure and mark the correct depth for insertion. Full insertion prevents leaks. Silicone wraps protect fittings underground. Supporting pipes after installation prevents side loads and leaks. Winterizing pipes with insulation protects against freeze damage. Regular inspections and using the right materials, such as resilient O-rings, help maintain waterproof integrity over time.

Tip: Always follow manufacturer guidelines for installation and maintenance to ensure long-term reliability.

Selecting certified waterproof connectors ensures safer and longer-lasting commercial installations.

- UL Listed connectors resist corrosion and moisture, protecting against short circuits and electrical fires.

- Secure locking and strain relief features prevent accidental disconnections.

- Proper installation and regular inspections help maintain reliable performance in demanding environments.

FAQ

What does the IP rating mean for waterproof fittings?

The IP rating shows how well a fitting blocks dust and water. Higher numbers mean better protection. For example, IP68 means total dust protection and long-term water immersion.

How often should technicians inspect waterproof fittings?

Technicians should inspect waterproof fittings every six months. Regular checks help spot wear, damage, or leaks early, keeping systems safe and reliable.

Can waterproof fittings be used outdoors year-round?

- Yes, waterproof fittings work outdoors all year.

- They resist rain, snow, and sunlight.

- Always choose fittings with the right rating for your environment.

Post time: Jun-18-2025